ManufacturING

How it's Manufactured

Proscaf is manufactured in our ISO9001 certified factory, with each component masterfully crafted with the highest-grade materials, followed by a comprehensive quality control process to ensure they meet the high standards Proscaf is renowned for.

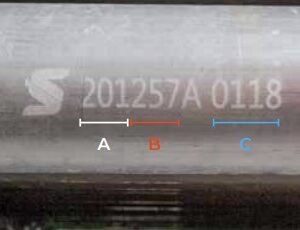

Each Proscaf component is individually batch-numbered for traceability and quality assurance, making the process of ordering spare or additional components effortlessly simple. Anything can be built utilising standard Proscaf components, from bridging, craneable, and cantilevered structures.

In addition to this process, a program of individual component testing is carried out in conjunction with independent testing agencies, to verify component consistency and strength. This is also used in engineering calculations vital to Proscaf technical data sheets on each component.

AS/NZS 1576

BS EN 12810

Quality You Can Count On

QA/QC: What we check — and why it matters:

Independent QC team inspects every shipment

Measurements, galvanising thickness, finish: all verified

Factory batch-tests steel grade for compliance

In-house hot-dip galvanising ensures finish consistency

Roll-formed tube on-site for tighter quality control

Proscaf Steel is manufactured using hot dip galvanised high-strength steel. Our in-house Proscaf engineers follow a vigorous quality control process that involves cross-checking measurements, galvanising thickness and overall finish.

Our factory houses its own hot dip galvanising plant, with each batch having a report produced detailing the properties of the metal. There is no compromise when it comes to the consistent quality of our product, which allows Proscaf to achieve the extraordinarily high loadings that it is renowned for.

Proscaf Aluminium is ideal for those projects where the locking and load bearing properties of Proscaf steel components are required, but you need the lightweight and installation advantages that aluminium delivers.

Aluminium is quicker to erect, demands less wear and tear on workers, allows more components to be transported on a truck and provides easier access to challenging worksites. Proscaf Aluminium has been designed and tested for optimum strength and durability ensuring that it is suitable for all site conditions.

Continuous Improvements

We’re committed to improving the efficiency and safety of our clients, with our R&D team utilising revolutionary intelligent scaffolding software to limit human error and developing new and innovative components that go through a rigorous testing process on an ongoing basis.

We’re devoted to bringing our clients the best possible scaffolding solution on the market.

Certifications

We understand that regulatory compliance is of utmost importance in every region we supply to. Proscaf components are designed- registered or certified as compliant with all safety and scaffolding-related regulations and standards, such as ISO:9001, AS/NZS 1576, AS/NZS 1577, and BS EN 12810.

The Proscaf system is registered with Workcover Australia and other equivalent peak bodies worldwide. Want to know if Proscaf is registered in your region, get in touch with us now.

GET IN TOUCH

If you would like to contact us about for more information on manufacturing, please contact us now.