Choose Type

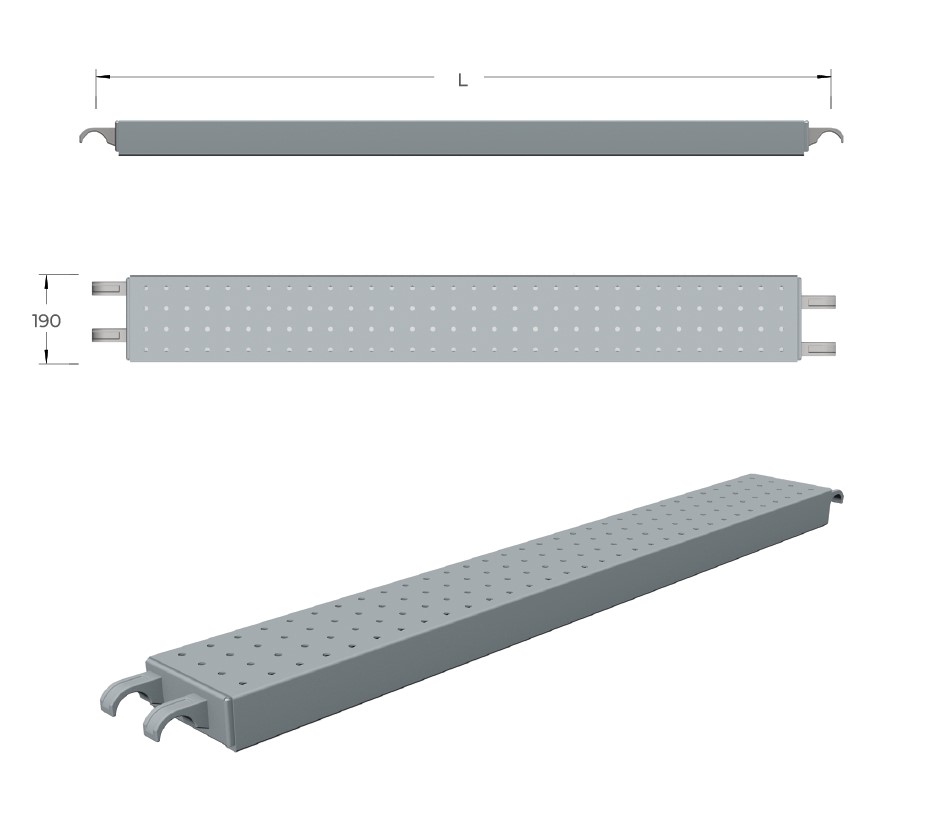

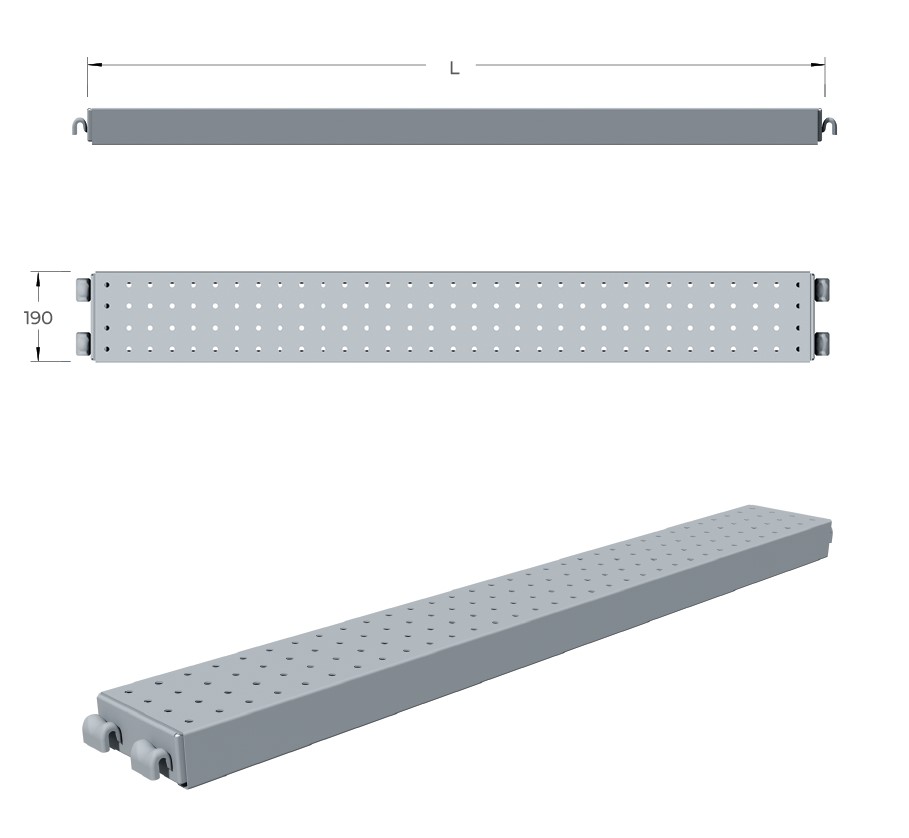

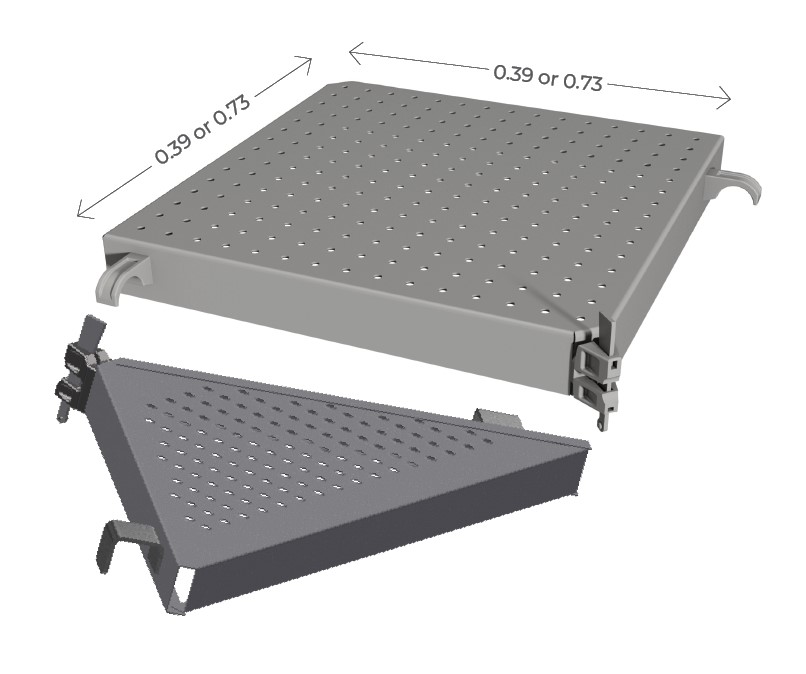

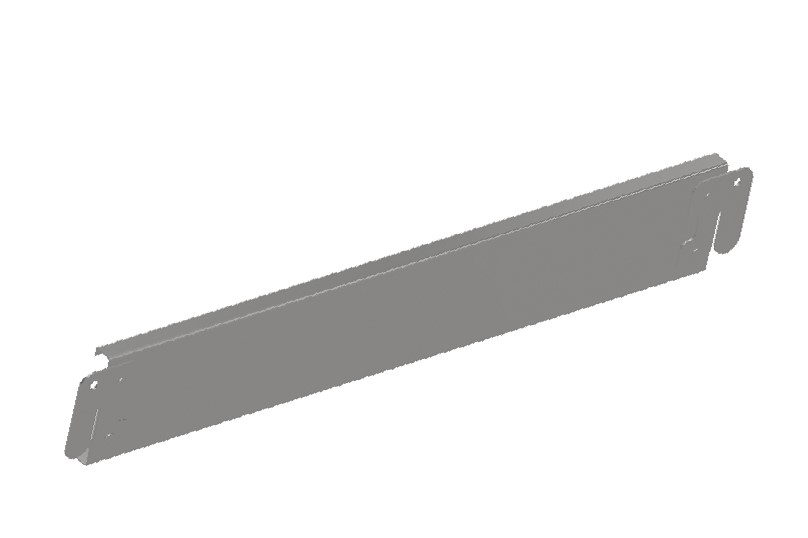

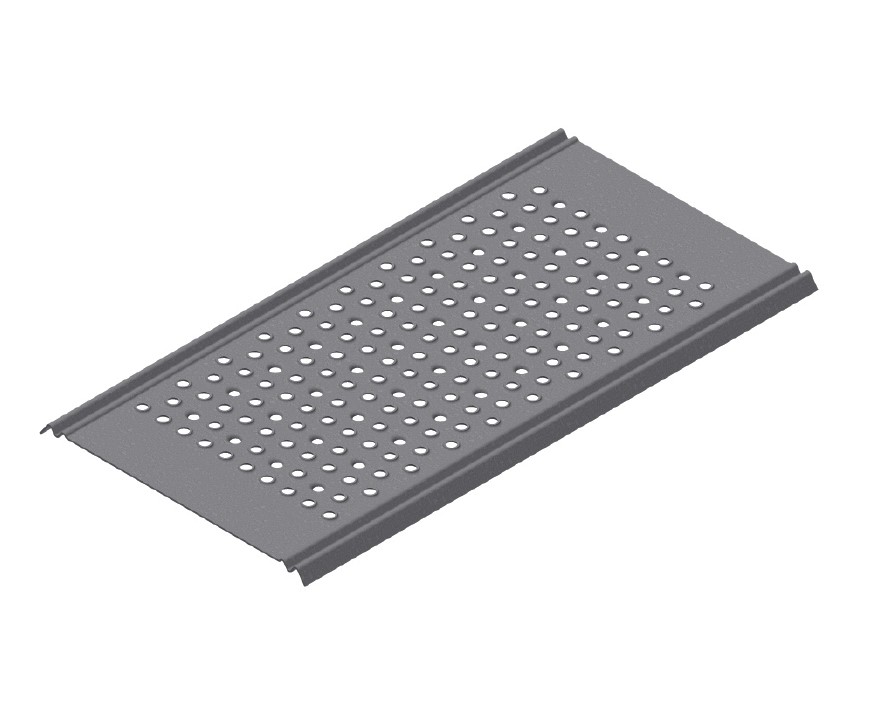

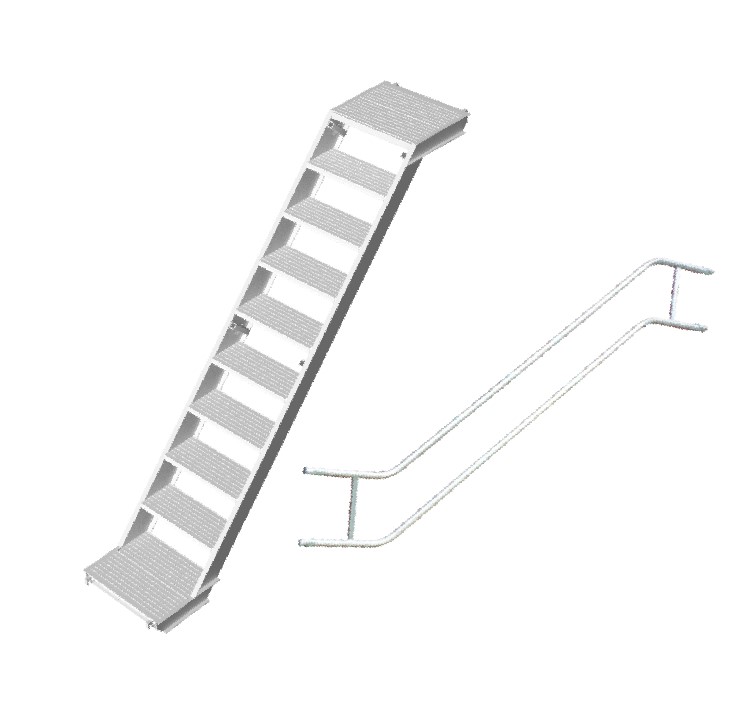

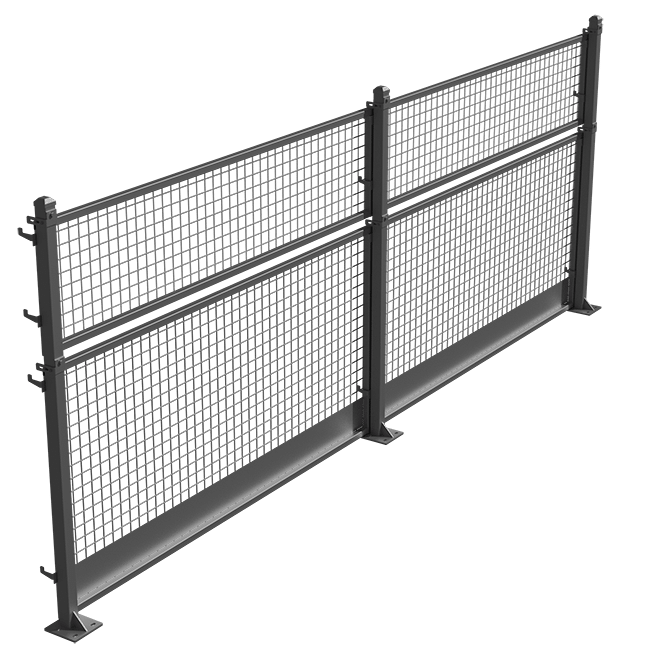

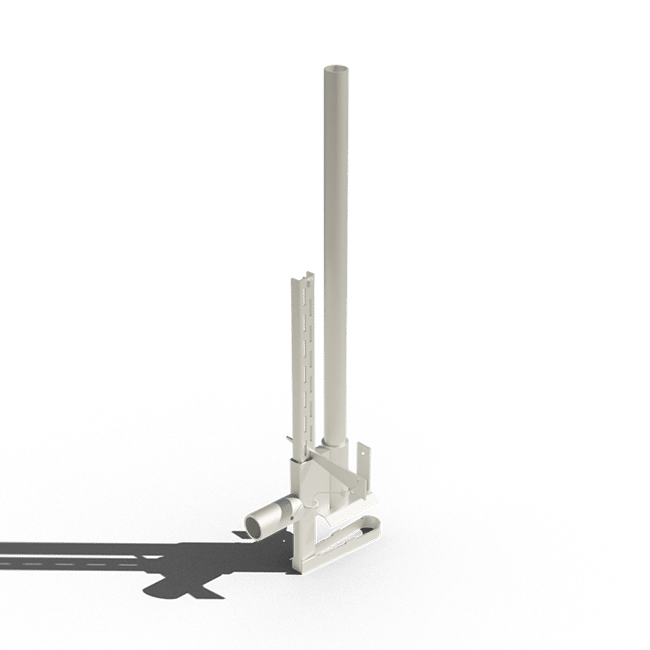

Steel Components

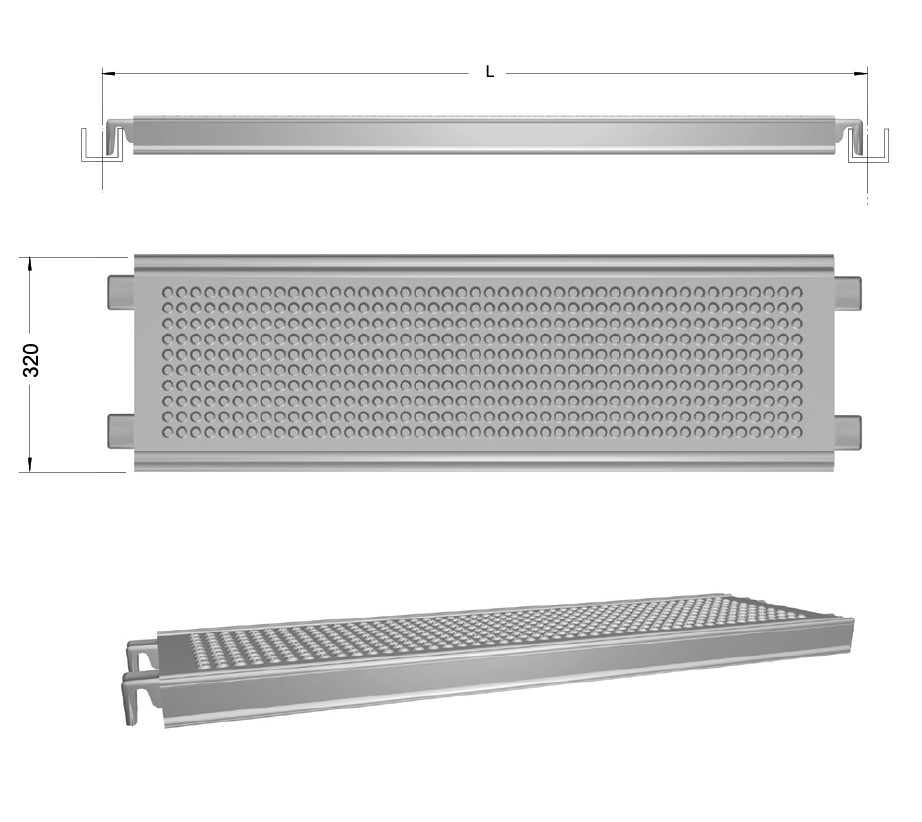

Aluminium Components

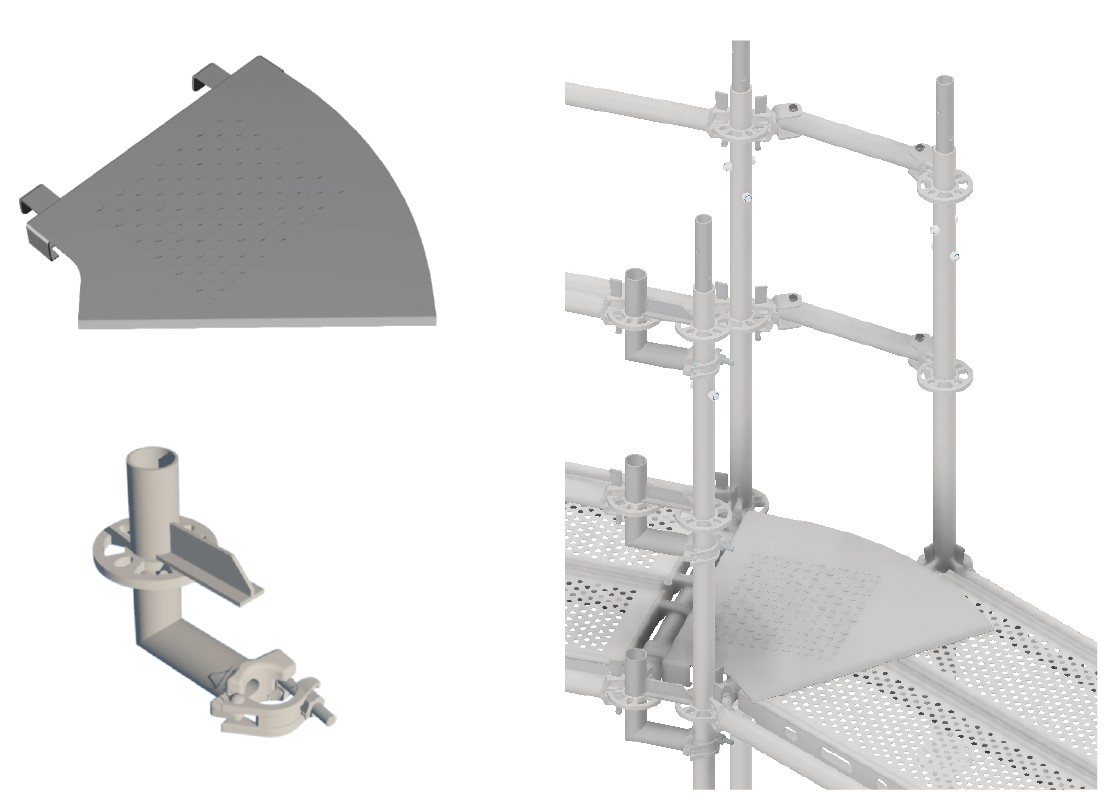

Ancillary Components

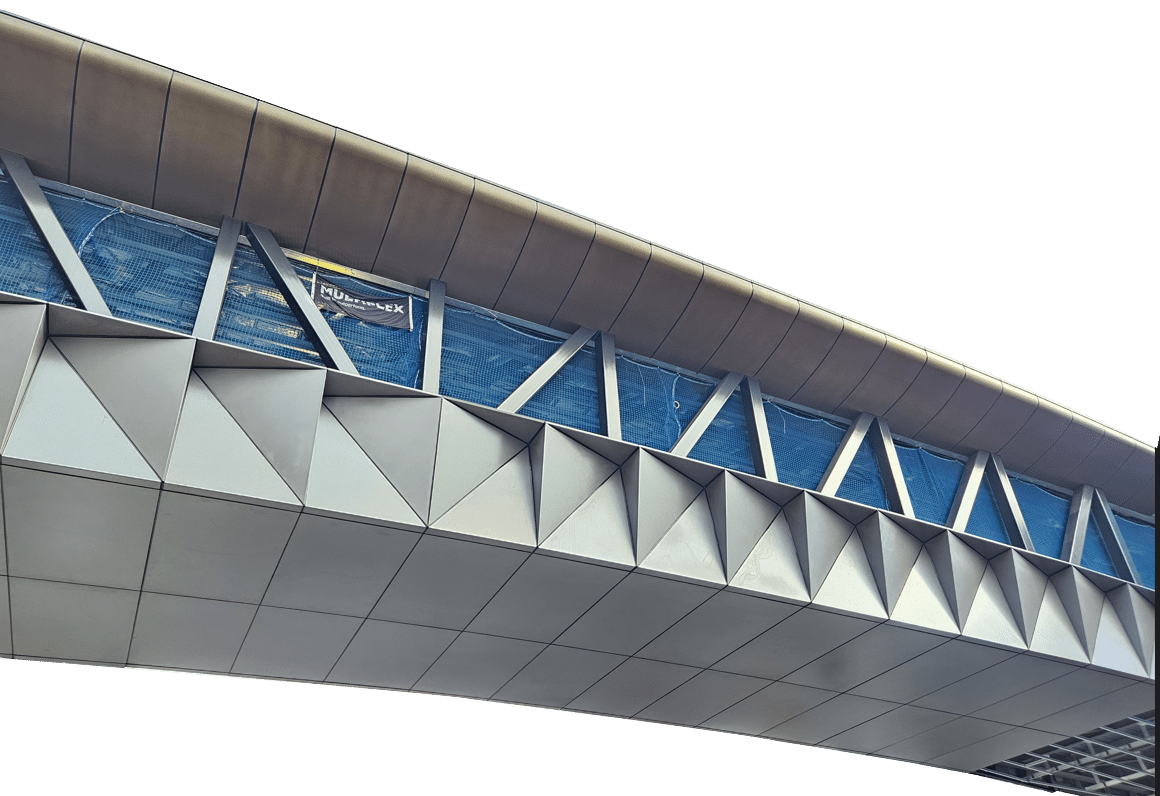

Overcoming Complexity in Scaffolding: How Proscaf Transformed a Challenging Project for H&H

In the scaffolding industry, experience can sometimes lead to scepticism – especially when a new system claims to outperform traditional tube and fit solutions. This was the case for Dean Turner of H&H Contract Scaffolding, who, after 35+ years in the industry, initially had reservations about moving to a new system. However, after completing a Proscaf Familiarisation Course, he and his team discovered how Proscaf could streamline operations, improve safety, and significantly reduce assembly time.

The Challenge: A Highly Complex Project

H&H Contract Scaffolding faced an exceptionally challenging project that demanded a flexible and innovative scaffolding system. The site featured:

- No 90-degree corners

- Two large splay angles

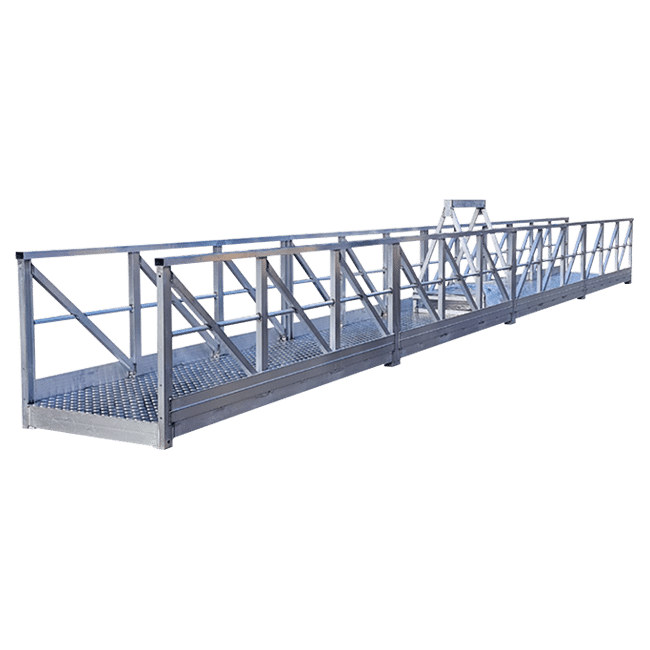

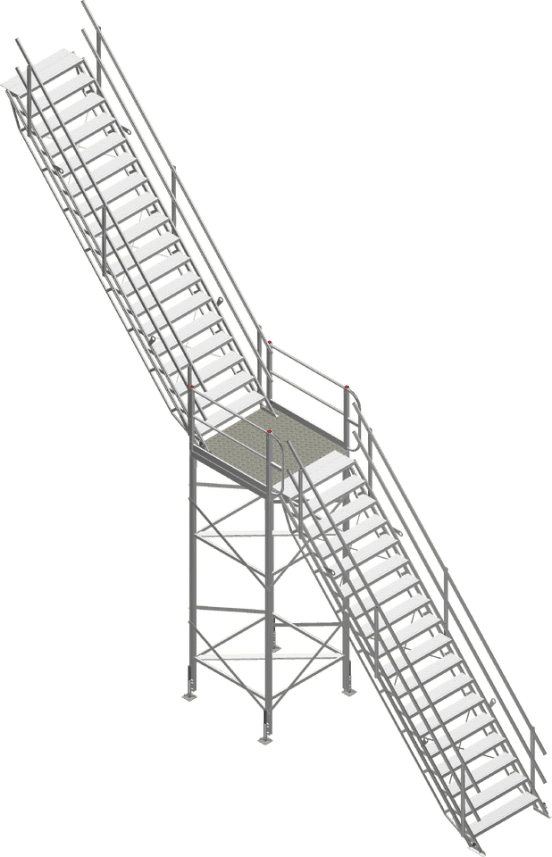

- A complex 2.57m x 207 x 4-lift pedestrian gantry access

- Stepped facades across the project

These structural demands required problems to be designed out, precise assembly, and seamless coordination, something that traditional tube and fit scaffolding struggled to accommodate efficiently.

The Solution: Proscaf’s Smart Engineering and Digital Support

Onsite teams often struggled to interpret numerous drawings and paperwork, leading to delays in construction and an increased risk of errors in scaffolding assembly.

Recognising the need for a more efficient and accurate approach, Proscaf’s in-house engineers developed an innovative digital scaffolding model using Scaffplan. This coloured 3D representation of the completed scaffold provided a clear visual guide, reducing complexity and improving assembly accuracy.

This enabled the H&H Team To:

- View the scaffold in 3D from any angle, including rotating it in any direction.

- Use mobile phones onsite to verify every component during erection.

- Reduce reliance on paper-based drawings, cutting down confusion and errors.

This proved to be a game-changer, as Dean Turner explained: “Not everyone can read numerous drawings onsite, too much paperwork, etc. Giving my guys a coloured 3D image to play with on their phones, whilst on the job, allowed everyone to see and understand the erection procedure of this system.”

The Outcome: Faster, Safer, and More Efficient Scaffolding

The benefits of switching to Proscaf were immediate and impactful. Key improvements included:

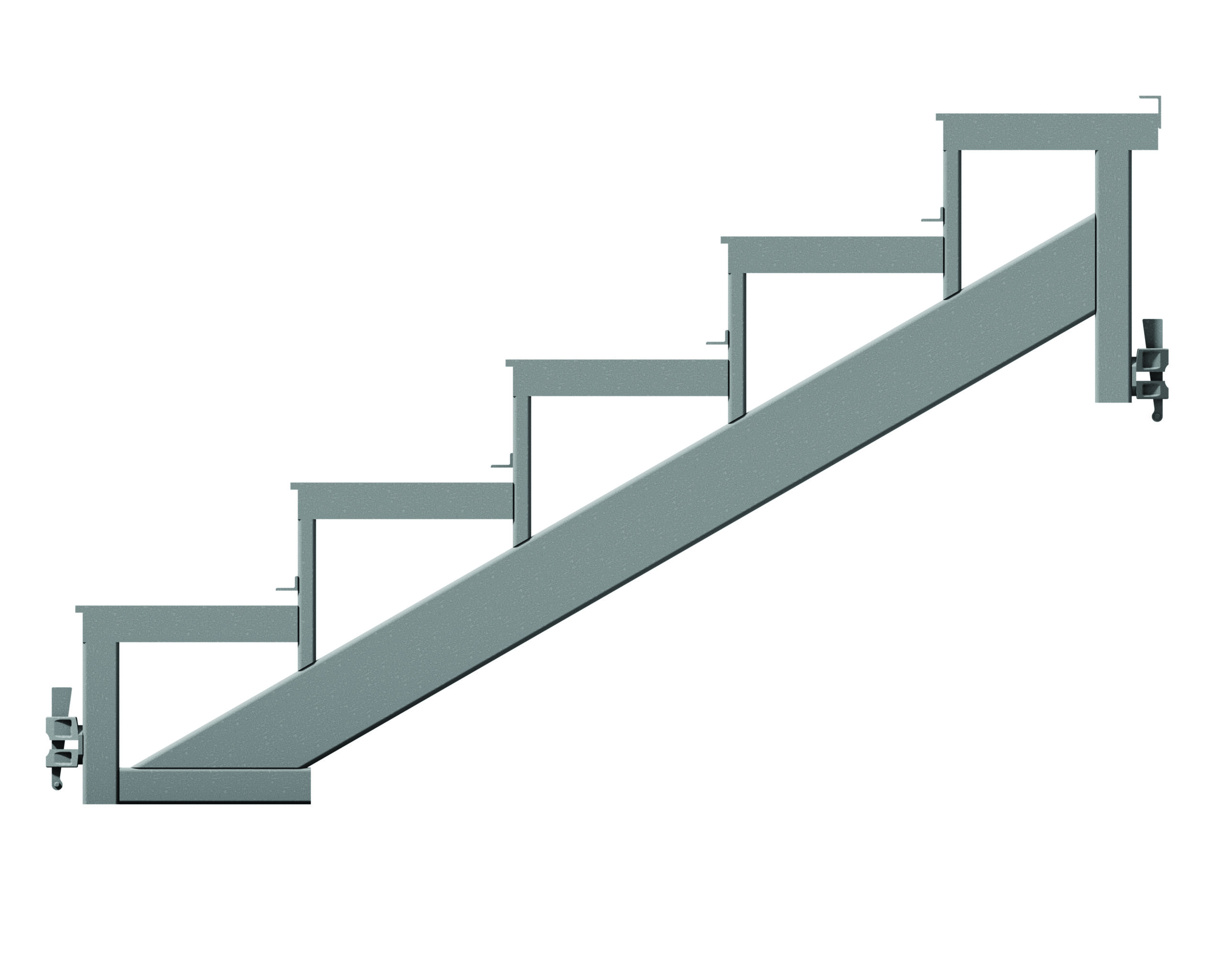

- Keeping Doorways Clear in a Medical Centre

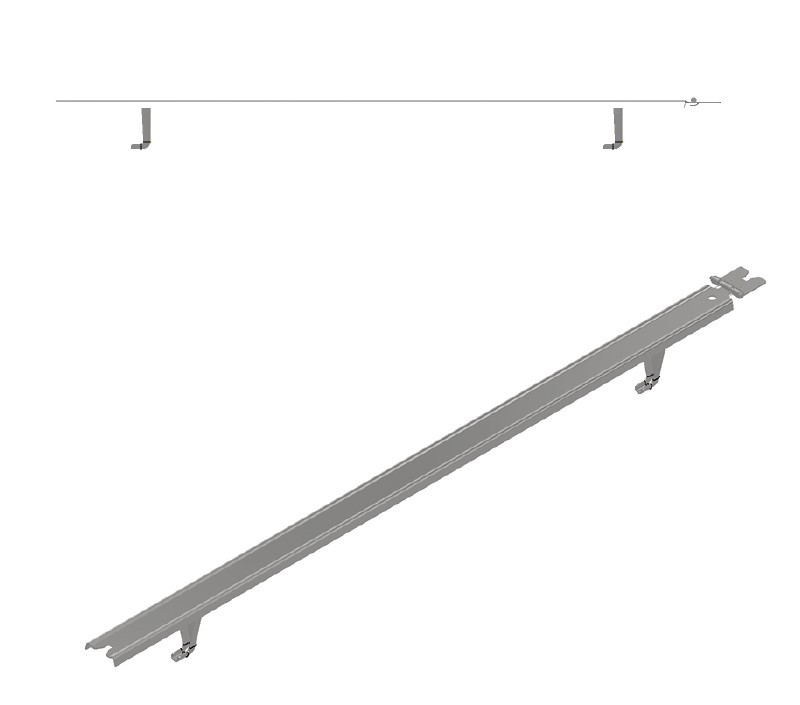

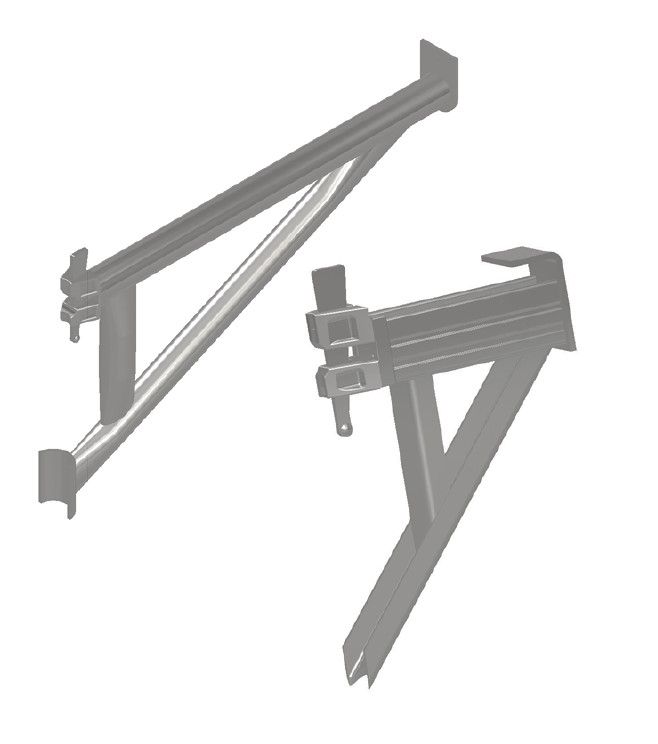

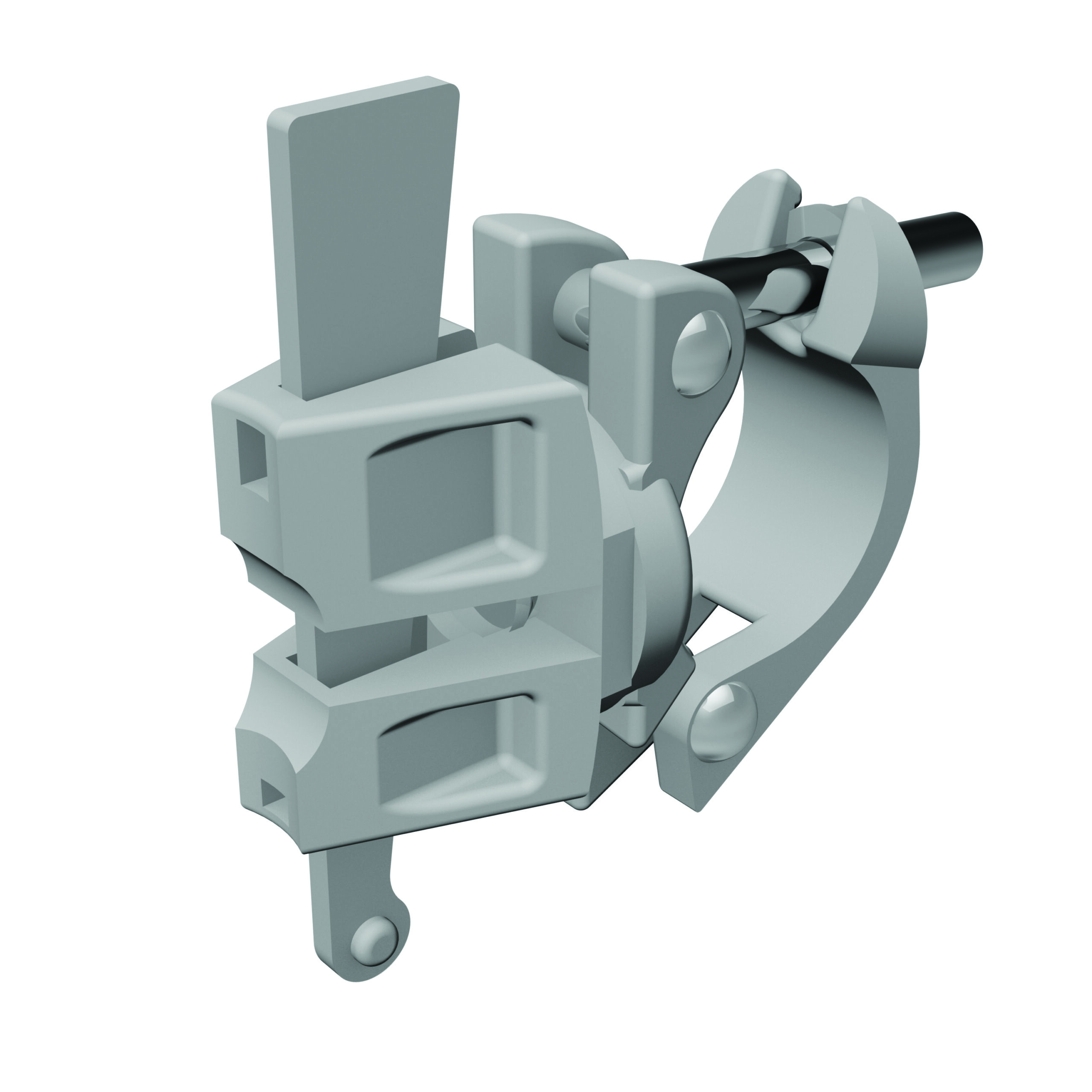

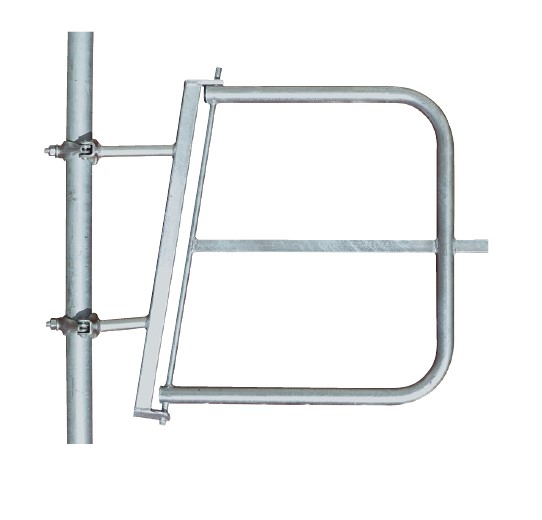

In one of the key areas of the project, 99% of doorways needed to remain clear, making traditional scaffold assembly impractical. Proscaf’s simple base collar and bracing solutions enabled the team to:

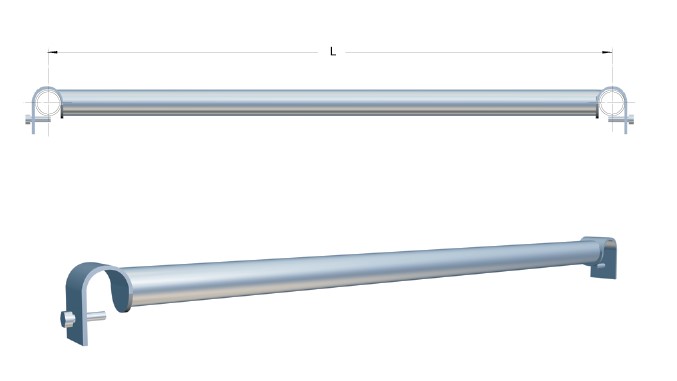

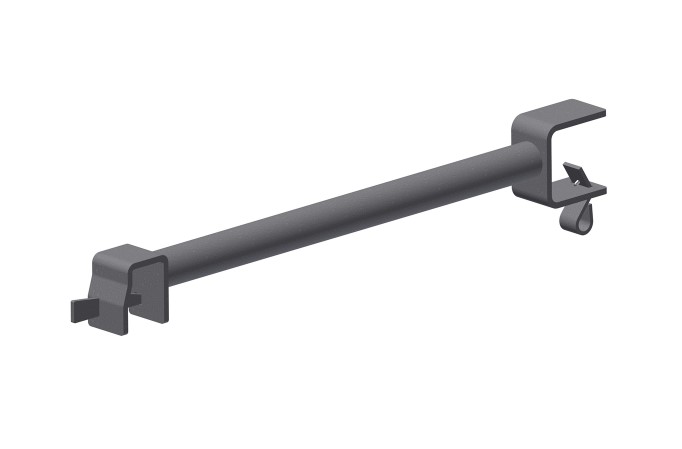

- Erect the ledger and transom directly into Proscaf’s simple base collar

- Pull the structure back with the Power of Proscaf Braces.

- Achieve a completely stable scaffold with zero drop or movement

Dean Turner described it as: “A very easy, quick, single-person exercise.”

- Creating Multi-Level Loading Bays in Record Time

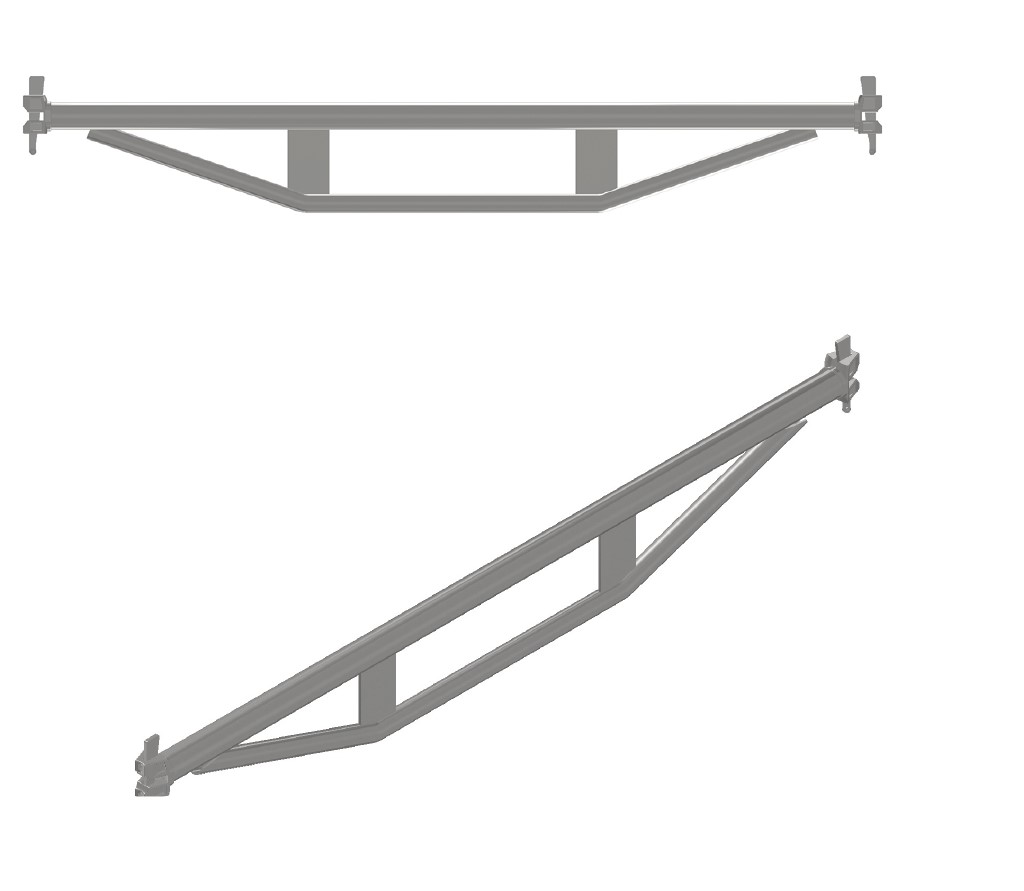

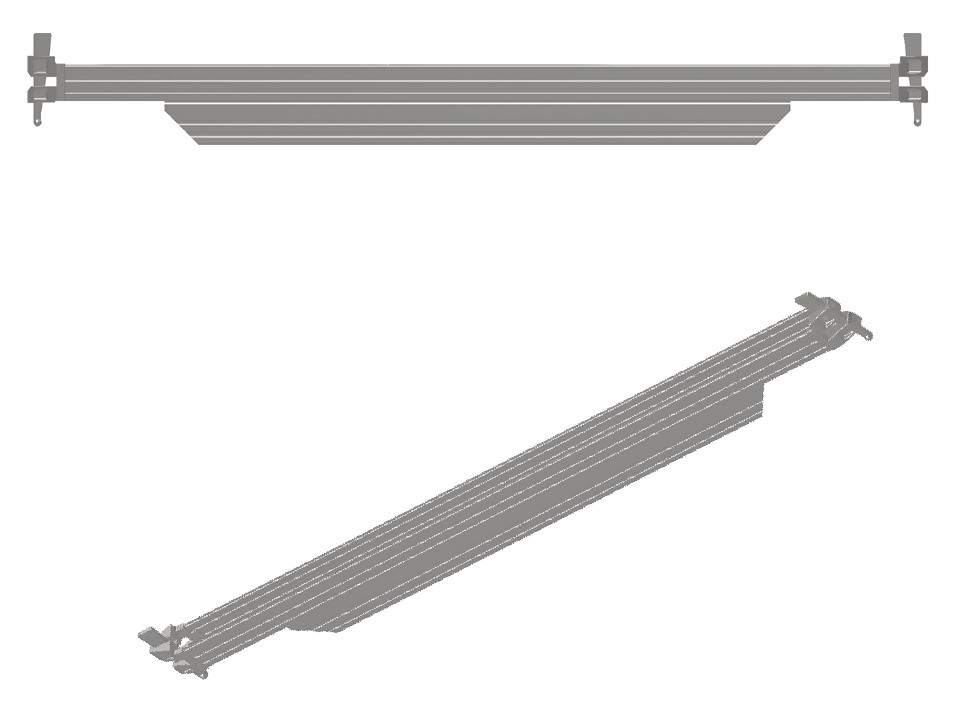

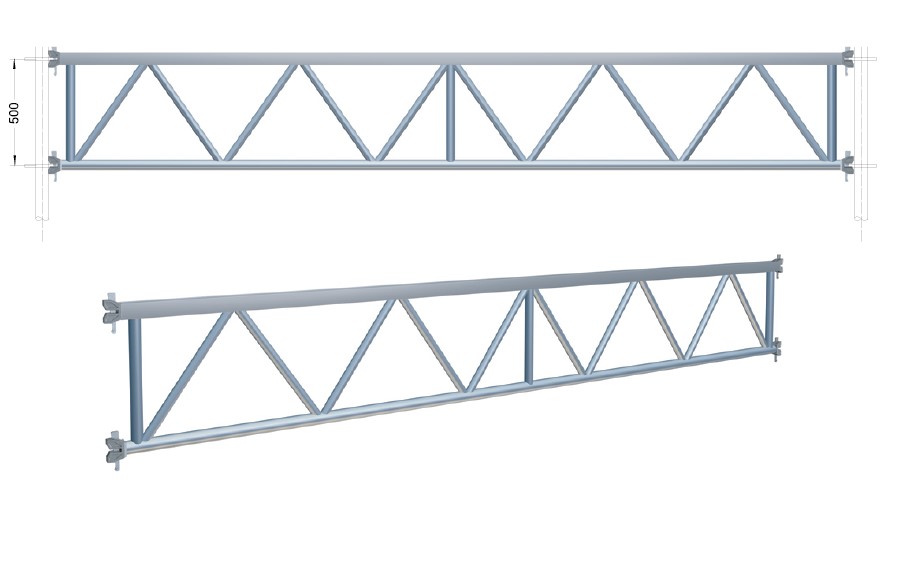

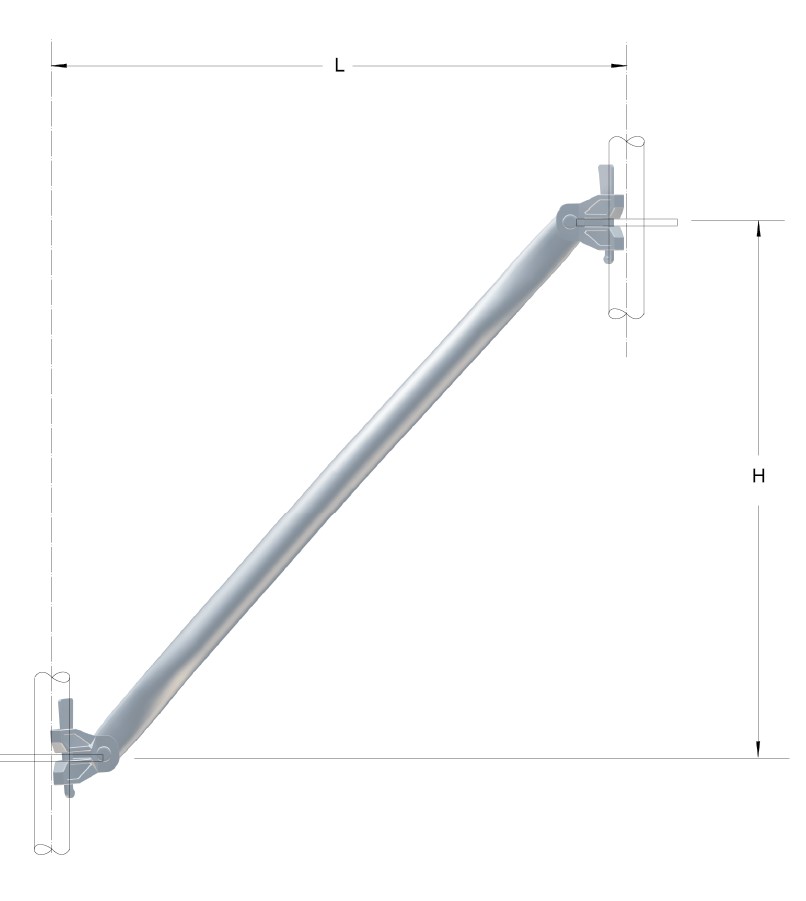

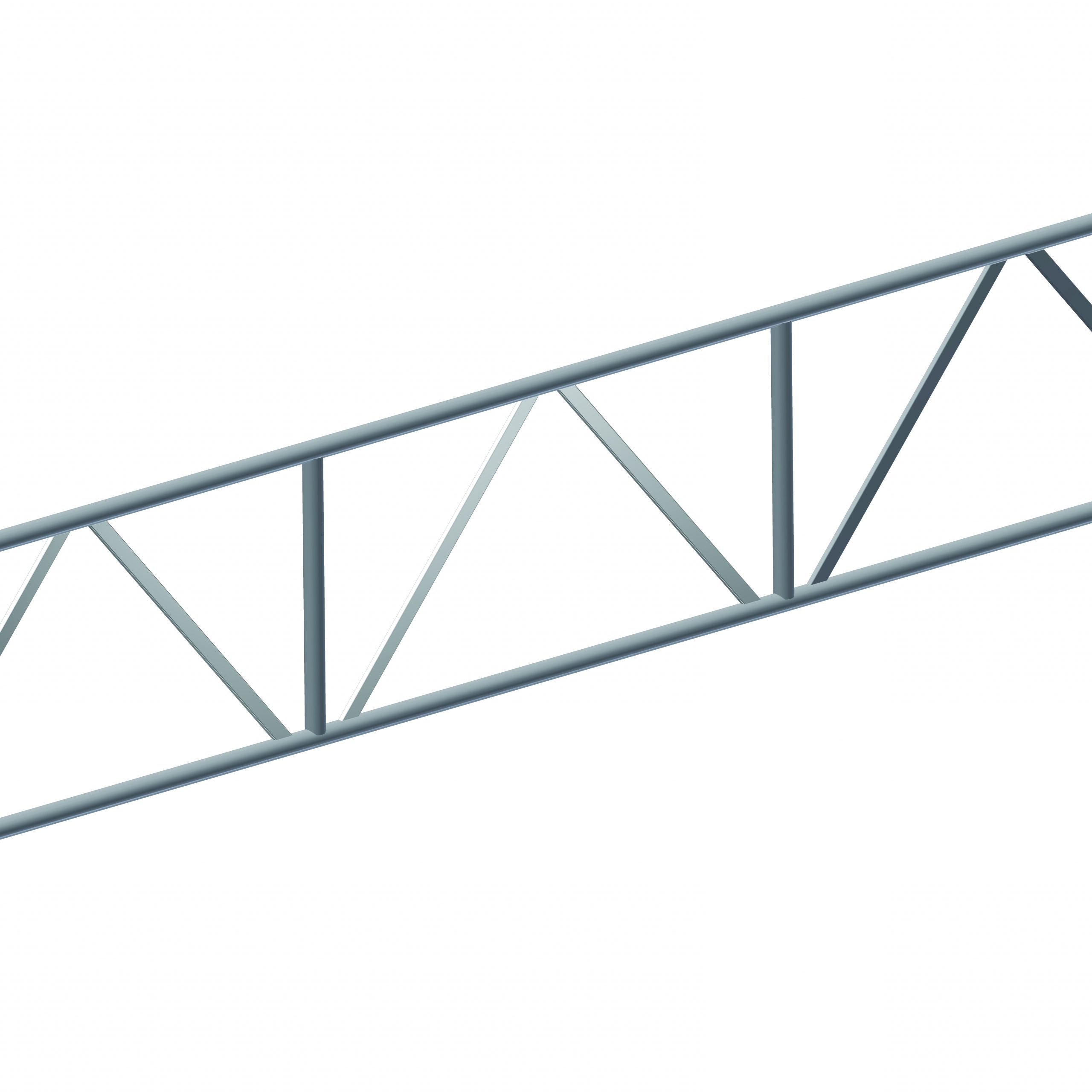

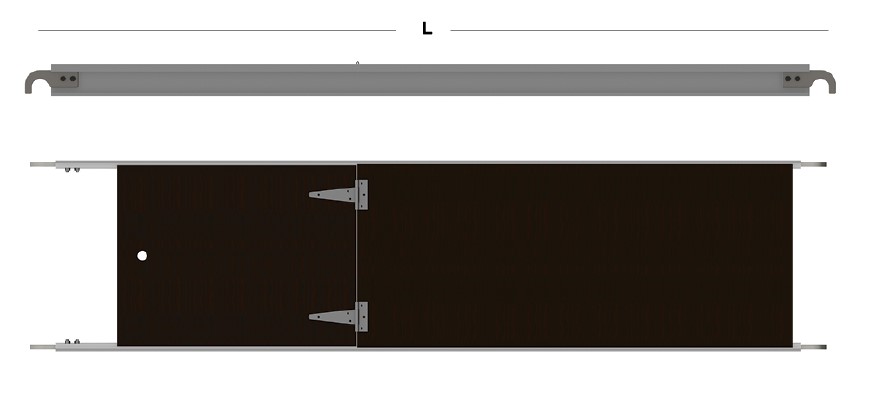

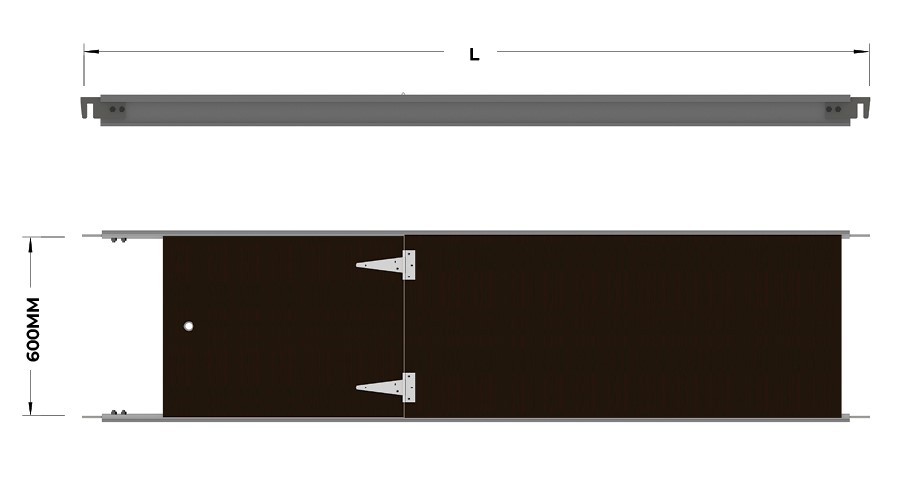

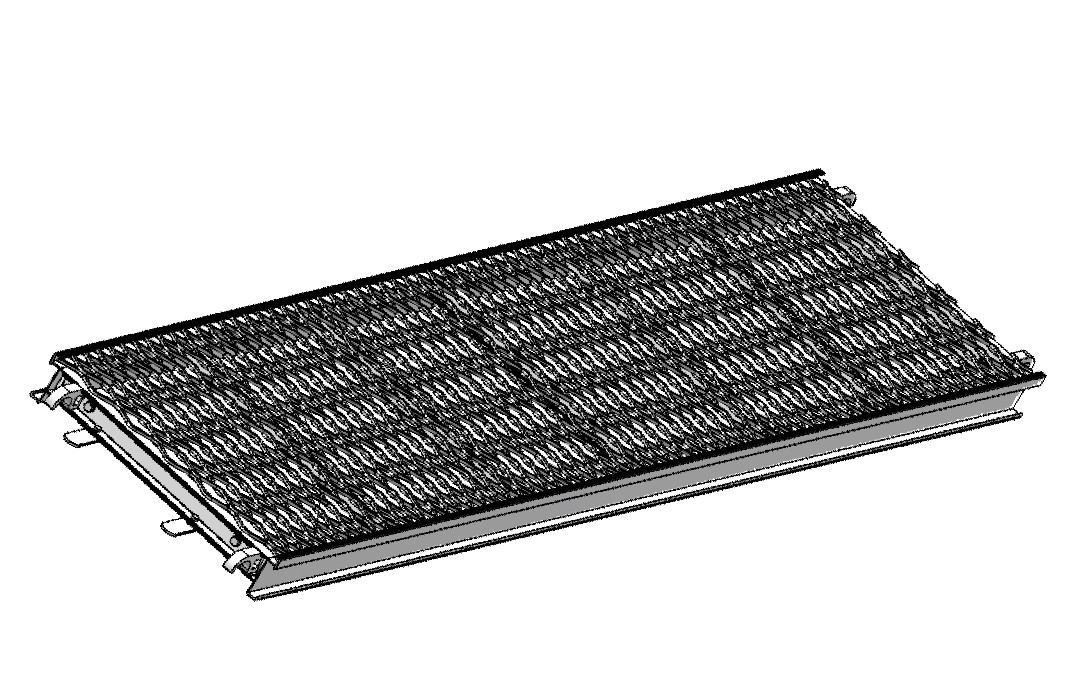

Using the 2.57m U-transom lattice beam, the team erected a 6-lift multi-level loading bay at record speed. Unlike tube and fit scaffolding, this solution eliminated the need for lacing and bracing throughout the beam, significantly cutting down erection time.

- Faster Erection Time and Continuous Support

The project highlighted Proscaf’s engineering precision and commitment to supporting customers every step of the way.

Dean Turner summarised the experience by saying: “Proscaf has provided a highly engineered system that has exceeded erection time far greater than any systems currently available, including tube and fit. The added configuration and flexibility made a significant difference, and the continuous support from Proscaf helped us through every stage of the project.”

A New Standard for Scaffolding Efficiency

What started as scepticism quickly turned into trust and advocacy for Proscaf’s system. H&H Contract Scaffolding not only overcame the challenges of this complex project but also set a new benchmark for efficiency, compliance, and safety.

Dean Turner’s final words sum up the Proscaf experience perfectly: “An exquisite, compliant, safe, smart access system – delivered on time.”

Ready to experience the Proscaf difference for yourself? Contact us today to see how our engineered scaffolding solutions can transform your next project.

Benefits of Lightweight Scaffold | Chris Polaczuk

We have recently been in touch with Chris Polaczuk and he was happy to share his feedback and the feedback from scaffolders on Proscaf Aluminium lightweight scaffolding. Read below to find out the benefits of the system he has noticed through his experience in the industry.

(Image: Chris Polaczuk, Programme Manager at Construction Health and Safety NZ – CHASNZ)

“Proscaf Aluminium is an efficient system that has been designed and tested for optimum strength and durability in site conditions. Perfect for projects where you need the locking and load bearing properties of Proscaf Steel, but you need the light weight and installation advantages that aluminium delivers.”

“Recent research shows that the weight of objects we carry at work is a major contributor to the wear and tear musculoskeletal problems which plague the NZ Scaffolding Industry. Therefore, the less weight our people handle throughout the day the less chance there is of wear and tear or acute, sudden injury.”

“Less weight handled = Less injury.”

“Talking with Scaffolders at Advanced Scaffolding in Petone who use Proscaf Aluminium lightweight scaffolding, there are common themes emerging of the benefits:”

- “I am no longer ‘shagged out’ at the end of the working day so I can do things with my family outside of work”

- “This might help me stay on the tools a bit longer”

- “Its way faster to erect and disassemble taking away time pressure”

- “Way lighter to lug up Mount Vic”

- “After using it, it’s very hard to return to the full weight stuff”

“It seems that the fact that they use Proscaf Aluminium lightweight scaffolding is a real draw card to workers staying at this business.”

“Mike Robins (owner) says it’s just good for business:”

- “The extra cost is easily recoverable in a short time by the savings made elsewhere.”

- “It is mostly applicable in residential work which is the largest sector of the trade.”

- “It has roughly the same life span as traditional steel.”

- “It helps reduce absenteeism especially on Fridays and Mondays.”

- “It is gender, injured and older worker friendly, opening more opportunity for diversity in the industry.”

- “It reduces wear and fuel on trucks, and they are faster to load and unload.”

Women in the Workforce: How Proscaf Aluminium is Breaking Barriers in Scaffolding

The scaffolding industry has long been seen as a labour-intensive field, traditionally dominated by males which is traditionally not hard to work out why: Putting up steel scaffold components = heavy lifting. But the landscape is shifting.

The answer is simple: If scaffold was lighter, more people could work in the industry including women and older people.

Proscaf Aluminium is exactly that. Proscaf Aluminium is 46% lighter than most steel scaffolding systems, significantly reducing fatigue and injury risks. Workers no longer need to strain themselves lifting heavy components all day — a major advantage for women entering the field, and for anyone concerned about long-term musculoskeletal stress.

Listen to Poppy from Limitless Scaffolding explain the benefits of the Proscaf scaffolding system above. As she said “It isn’t as hard as it looks from the outside”.

When asked about Proscaf Aluminium Poppy explained “By the end of the day, you feel so much better because you are lifting half the weight compared to steel”.

Why Proscaf Aluminium Makes a Difference

The scaffolding industry has historically been dominated by men due to the physical demands of handling heavy steel systems. But Proscaf Aluminium is changing the game making it possible for women, older workers, and others outside the traditional labour pool to step into scaffolding roles with confidence and safety.

Here’s why:

46% lighter than most steel systems

The reduced weight significantly cuts down on fatigue and injury risks. Workers don’t have to strain themselves lifting heavy components throughout the day which is a key advantage for women and anyone concerned about long-term musculoskeletal stress.Up to 28% faster to install

Upon doing a real-life case study, we proved that installation and dismantle times on a standard new build are cut by nearly a third using Proscaf Aluminium vs steel system. That’s more efficiency with less wear and tear on the body.Made from 6061-T6 marine grade aluminium.

This material has a strength-to-weight ratio twice that of steel, meaning it’s tough and reliable without the weight.Cost-effective and adaptable

Proscaf Aluminium suits everything from residential scaffolding to suspended platforms and complex cantilever jobs. It is particularly cost-effective on projects when the scaffold is only up for a short period of time and there is a lot of labour in a short period of time. It’s also compatible with Proscaf Steel enabling both systems to be used together as required.

Supporting Workforce Diversity Goals

Many large corporate construction companies are now actively working towards building a more balanced workforce, setting formal targets for gender diversity and broader inclusion. Lightweight and smarter systems like Proscaf Aluminium make these goals more achievable in traditionally physical roles, helping companies create safer, more accessible worksites for all employees. By making it easier for a wider range of people to work effectively on-site, Proscaf Aluminium supports companies not only in improving productivity but also in meeting their diversity and inclusion commitments.

Empowering Women Through Smarter Systems

With tools like Proscaf Aluminium, physical strength is no longer a barrier to entry. The smarter, lighter and faster Proscaf Aluminium system enables women and a wider range of workers to confidently take on scaffolding roles and lead on-site operations. It’s proof that the future of the scaffolding industry isn’t just about muscle, it’s about smart solutions, skill, and innovation.

Real Stories, Real Change

As demonstrated by Limitless Scaffolding, companies across Australasia are able to increase their talent pool of staff by using Proscaf Aluminium. Their contribution is reshaping what the future of scaffolding looks like: Smarter, safer, and more inclusive.

CONCLUSION

Investing in Proscaf Aluminium is not just about cutting install times or reducing labour costs it’s about expanding your workforce. When you use lighter, safer scaffolding, you’re opening up opportunities for:

Women who may have been discouraged by the physical strain of steel systems.

Older professionals who bring expertise but may no longer want to handle heavy gear.

Increased productivity and job satisfaction due to easier handling and fewer injuries.

Steel vs Aluminium Scaffolding Systems – How Do They Compare?

Proscaf Steel:

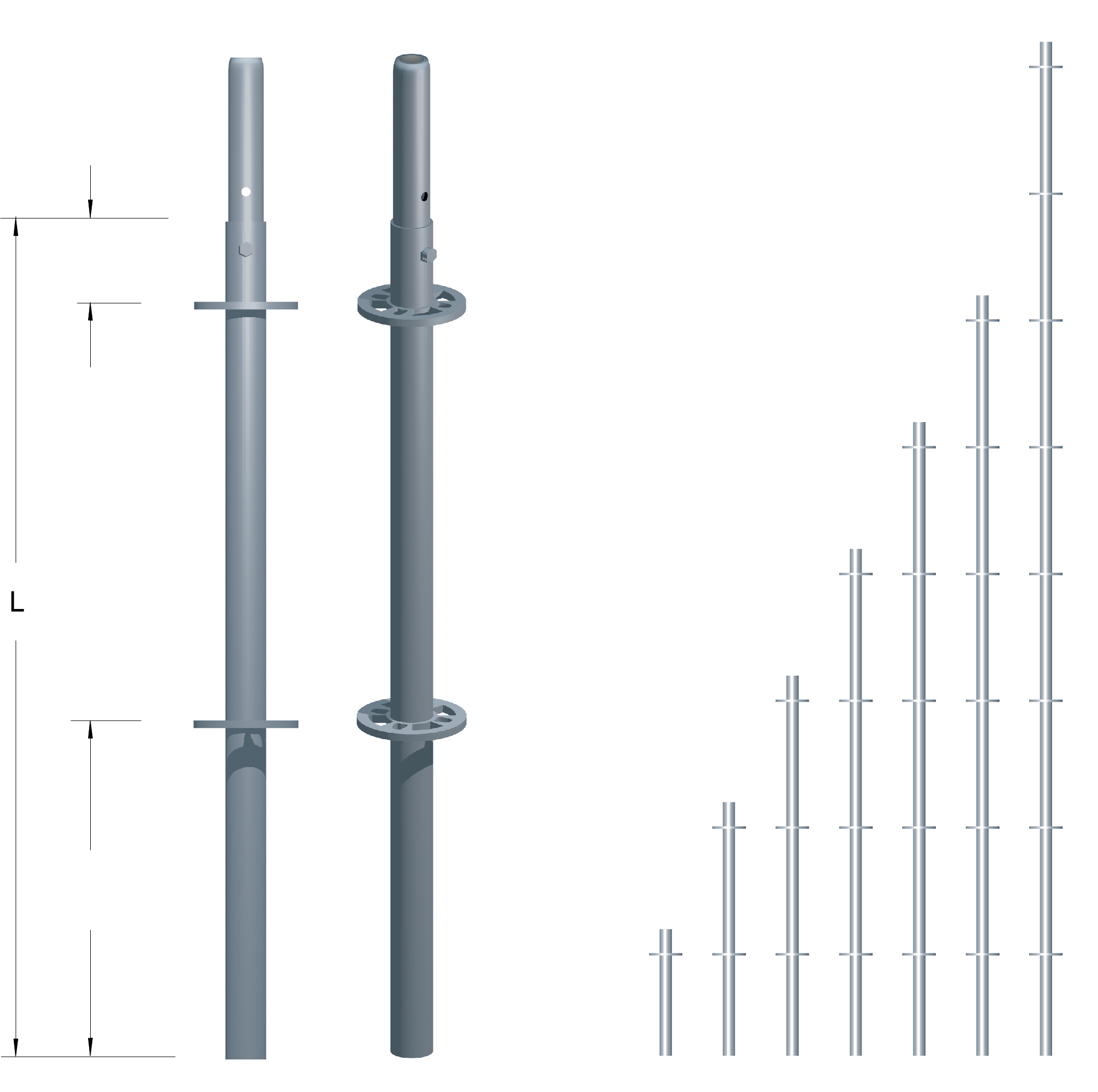

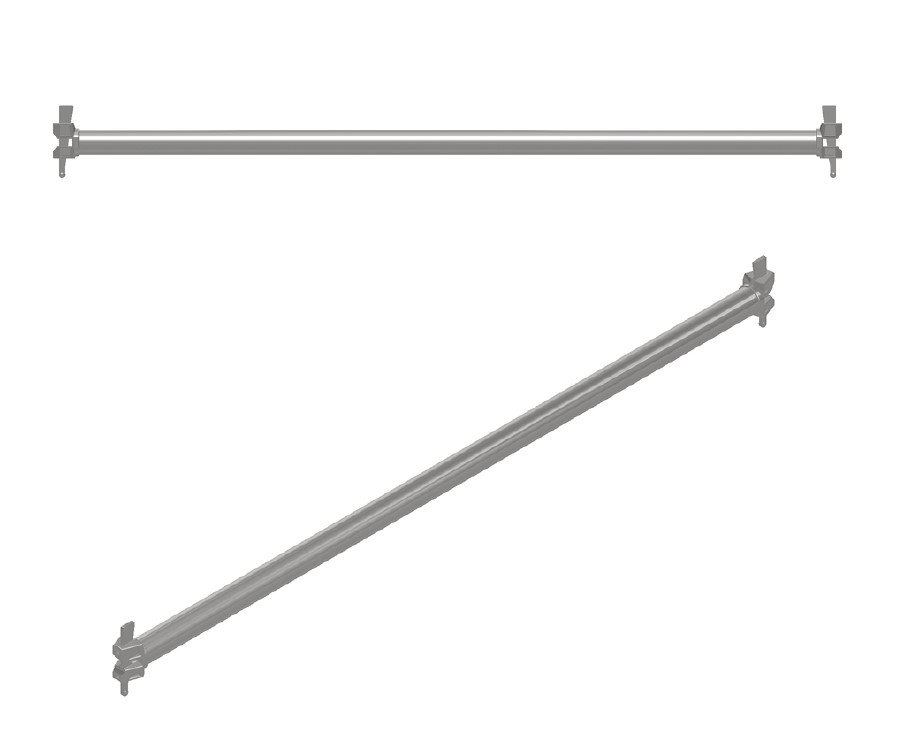

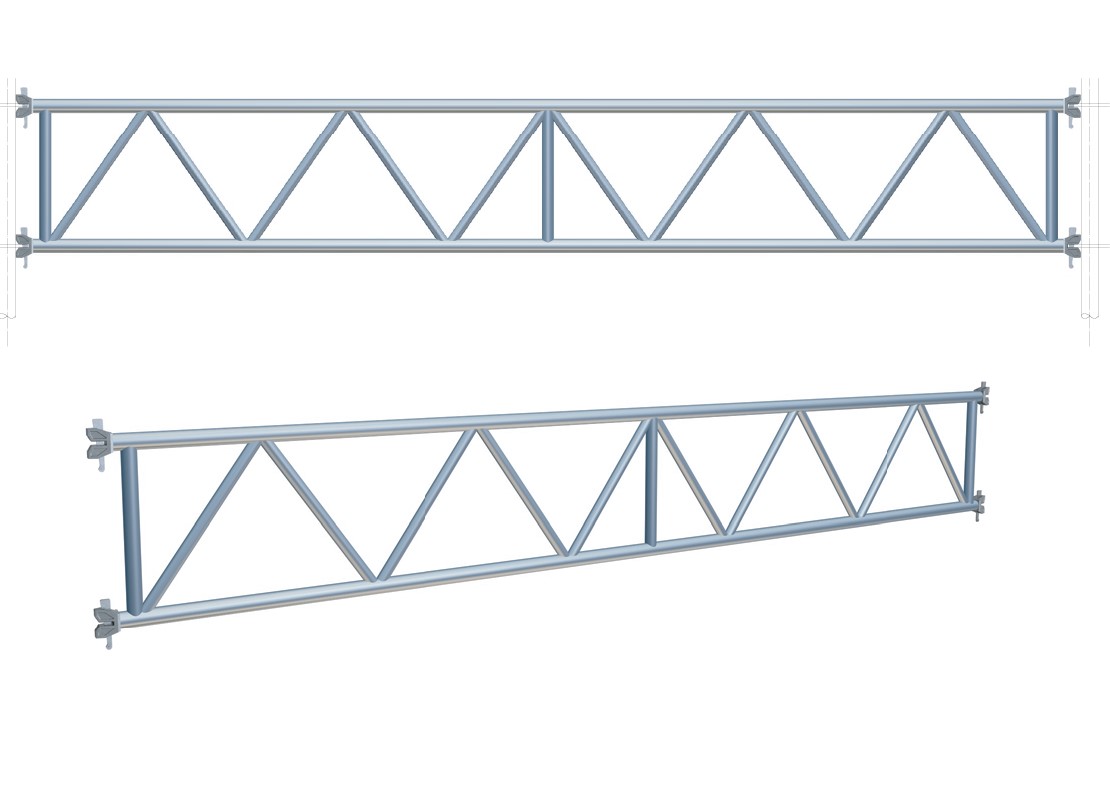

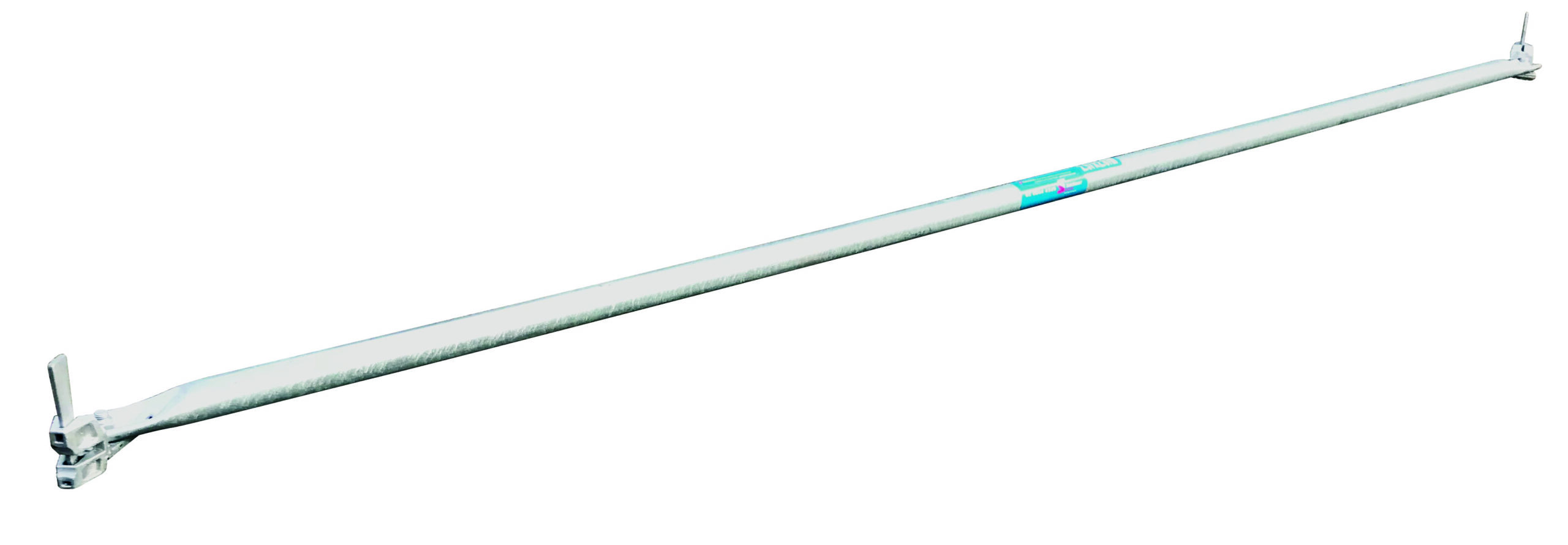

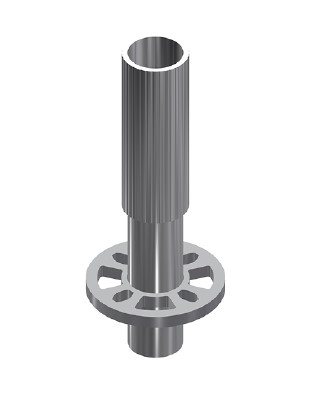

The Proscaf Steel Scaffolding System is a very popular and commonly used scaffolding system in NZ and AU. Proscaf Steel is a ringlock system and is the most efficient system scaffold on the market. Proscaf Steel has industry leading diagonal braces and therefore it can achieve more than most systems on the market. Proscaf steel can be used for a huge variety of projects from day-to-day façade scaffolding projects to heavy duty propping and cantilever scaffolding.

So, what’s the difference between Proscaf Steel and Aluminium?

Proscaf Steel and Proscaf Aluminium almost look identical and work together seamlessly. However, there are a few differences and applications that Proscaf Aluminium excels in. We cover this off below.

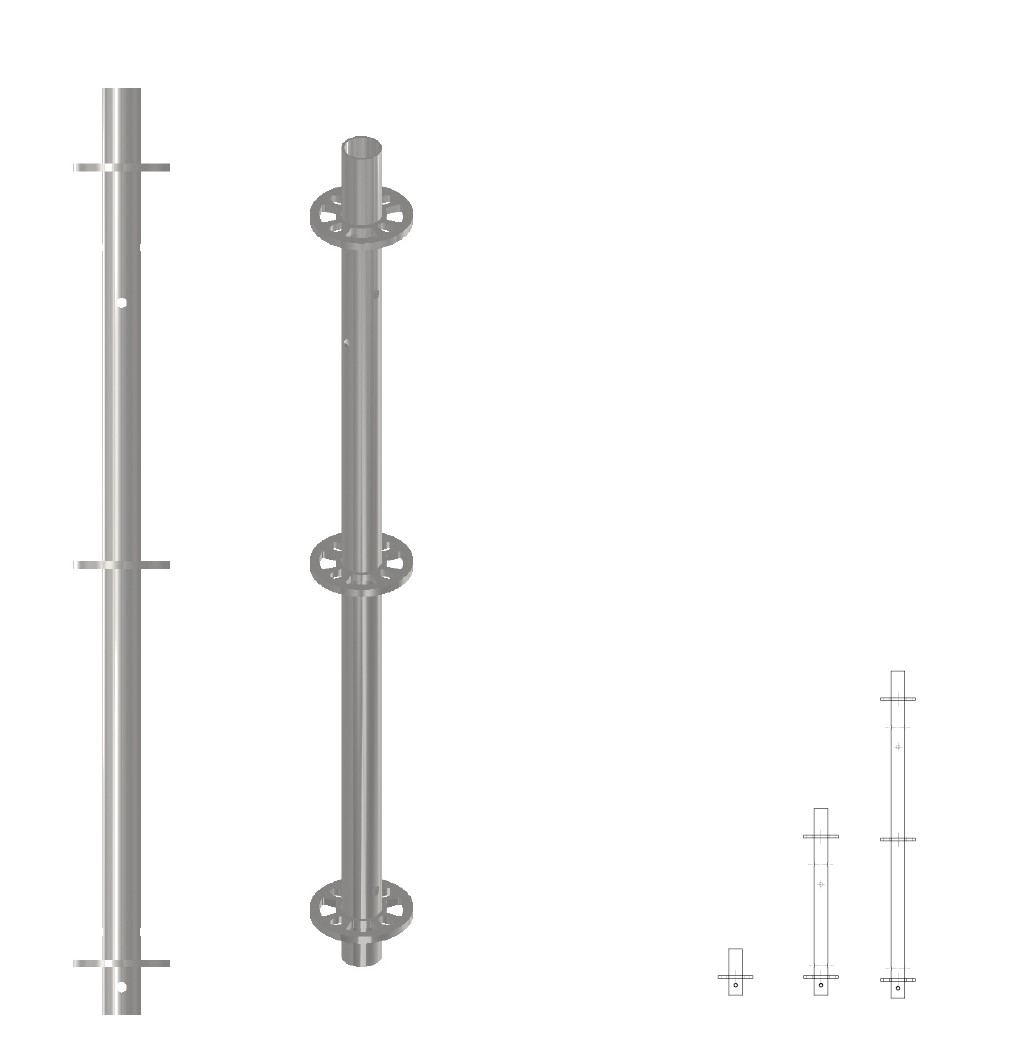

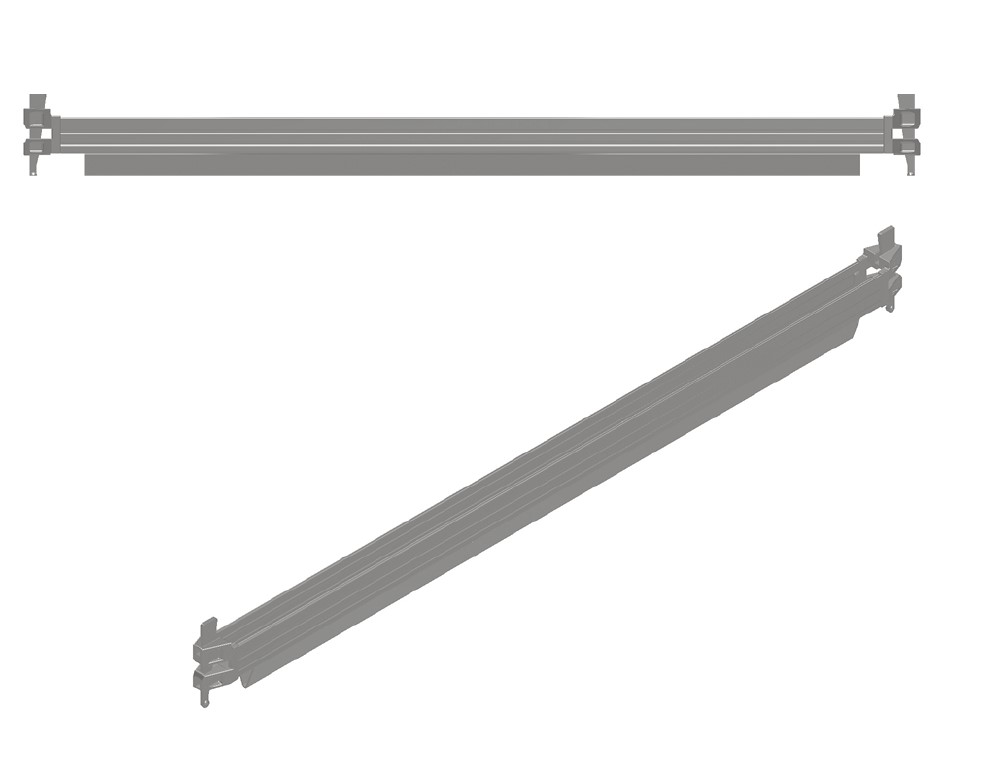

Proscaf Aluminium:

Proscaf Aluminium is a highly versatile system and integrates seamlessly with Proscaf Steel. The main difference is the weight of the system. Proscaf Aluminium is 46% lighter than Proscaf Steel which provides many benefits.

Before we dig in, we want to address a common misconception about Proscaf Aluminium. Aluminium scaffolding is not like aluminium scaffold towers. Unlike mobile towers which are modular and are used to access one area, Proscaf Aluminium is extremely versatile and can handle large loads.

When compared to steel, aluminium has a coefficient of elasticity equal to one third. In essence, its elastic deformation under a load is three times greater than steel. This means that Proscaf Aluminium has more flex than steel systems, giving the impression that it is weaker. This is not the case because while steel has a higher rigidity, the strength to weight ratio of steel vs aluminium is 2.8:1. Proscaf Aluminium has a thicker internal wall dimension than Proscaf steel to achieve its high weight rating. The outside dimensions of the system are the same as Proscaf Steel which means it is compatible with Proscaf Steel

Ideal Applications of Proscaf Aluminium:

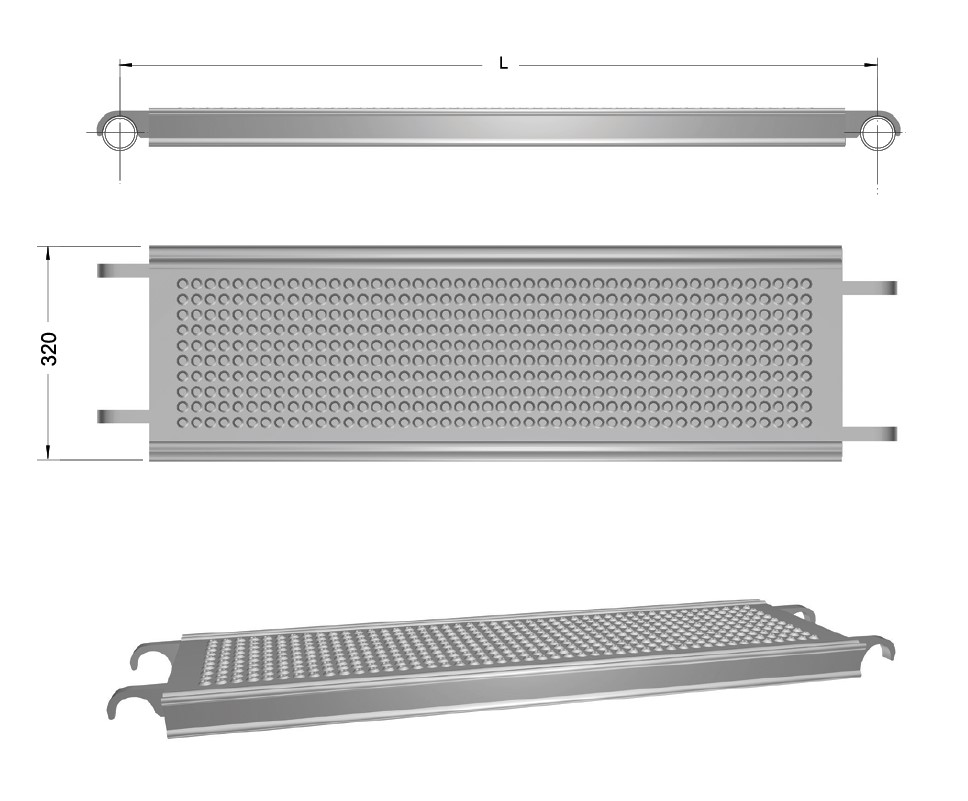

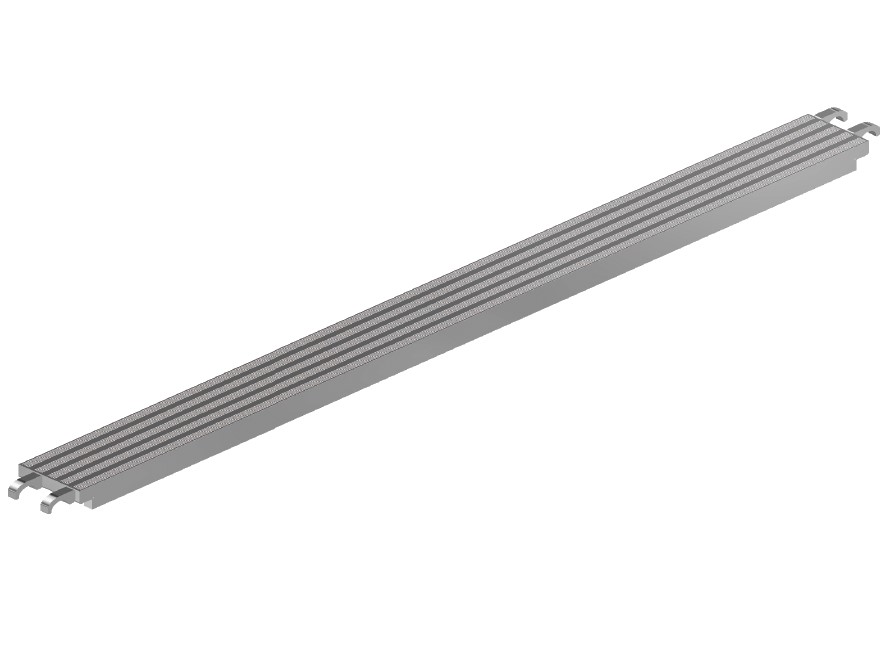

SCAFFOLDING FOR RESIDENTIAL HOUSING

The typical residential house scaffold only stands onsite for 4-6 weeks. The largest cost of the project to the scaffolder is labour in the erection and dismantle. Proscaf aluminium is 46% lighter than most steel systems: a scaffolder carrying 20kg of equipment means 2 x 3.07m steel ledgers or 5 x 3.07 aluminium ledgers. A recent case study proved that the installation and dismantle time on a single-story new build is reduced by 28% using Proscaf Aluminium. The time saved in transport and movement of Proscaf Aluminium has been proven to be a more economical system for scaffolding short-term projects.

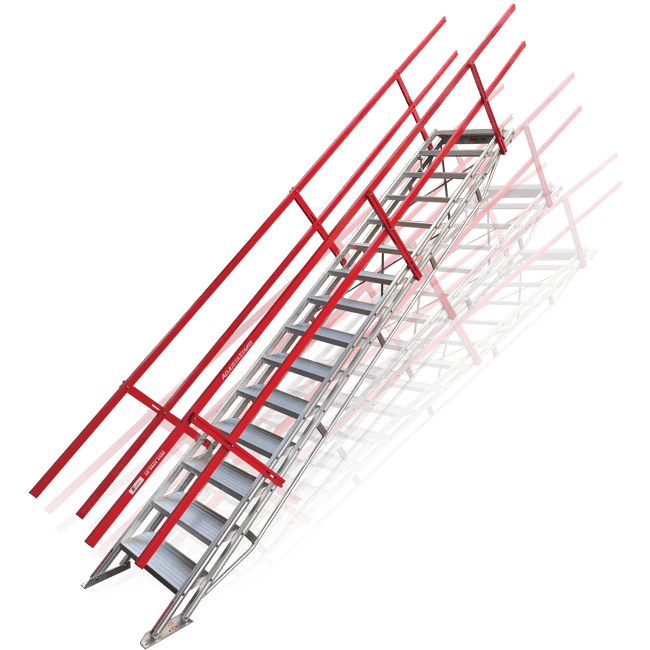

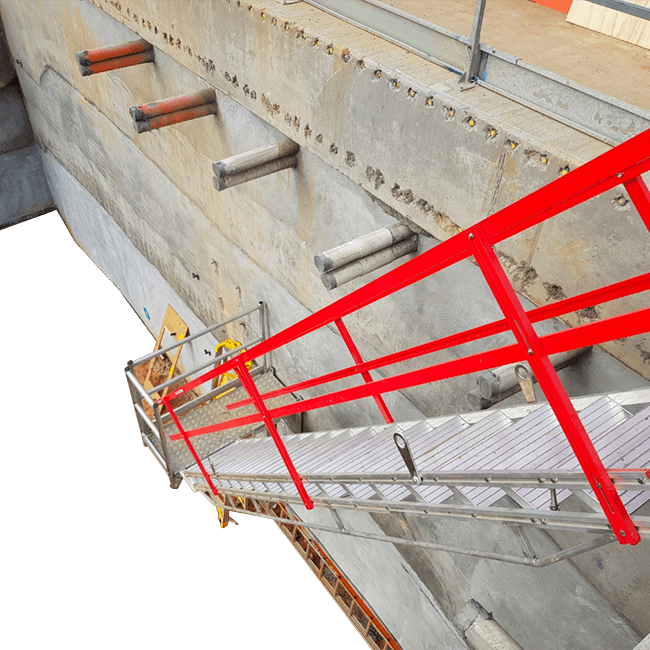

SUSPENDED SCAFFOLDING

Proscaf Aluminium is designed to be able to be used for suspended/ hanging scaffold projects. Proscaf Aluminium is a 6061-T6, marine grade aluminium. The strength to weight ratio of this grade of aluminium is twice that of steel allowing scaffold contractors to build suspended platforms with a lower tare weight. The extra-strong spigots are double bolted, suiting suspended scaffolding projects. The impressive strength to weight ratio of Proscaf Aluminium makes it suited for the maintenance of structures like wharfs and bridges that have weight restrictions.

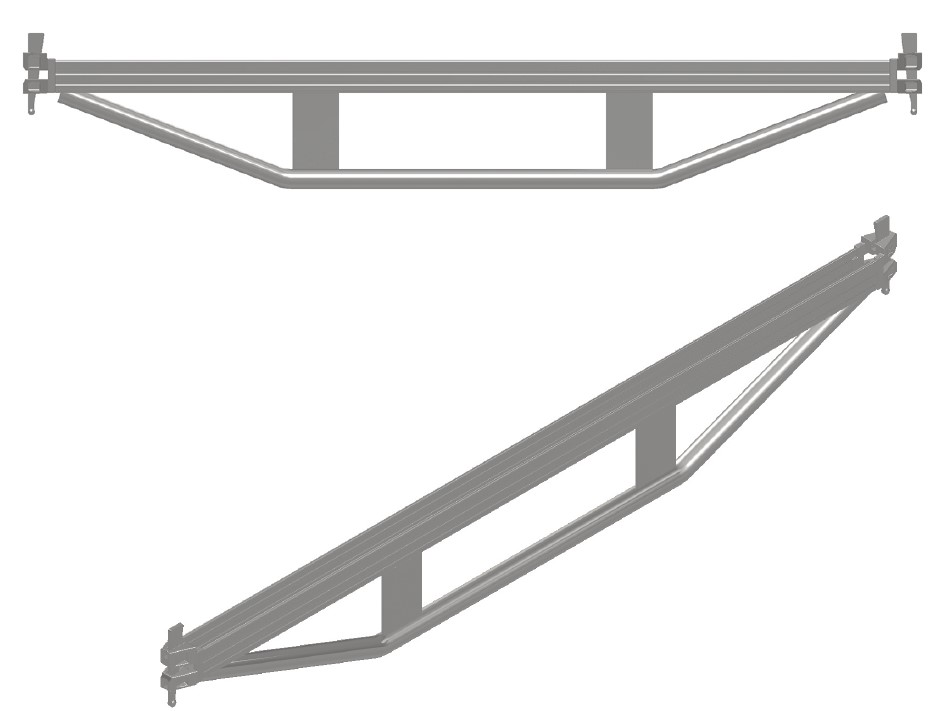

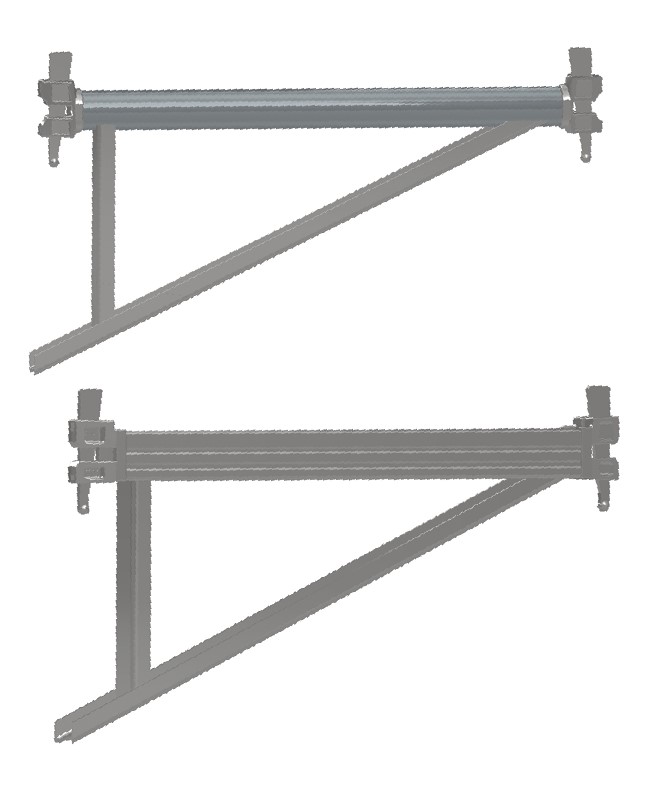

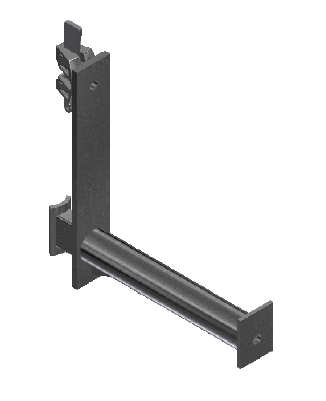

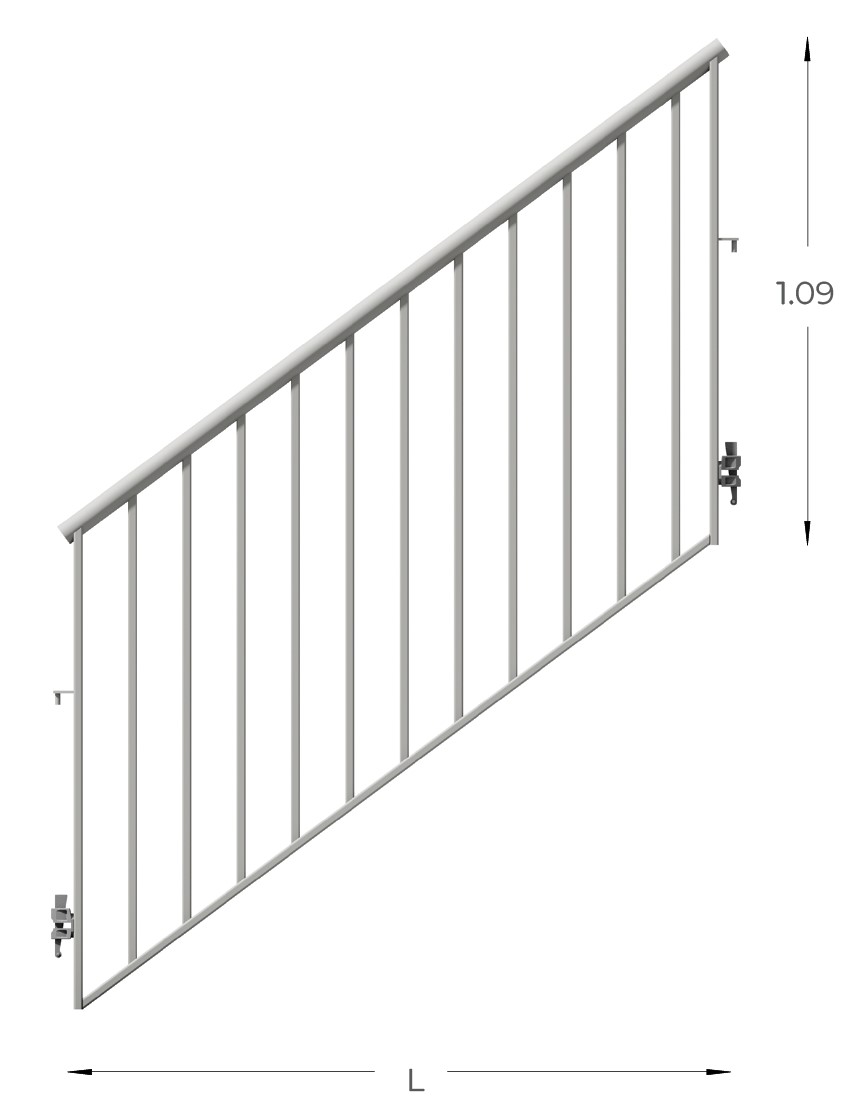

CANTILEVER SCAFFOLDING

Proscaf Aluminium is unique for its ability to cantilever using the load-bearing diagonal brace. With industry high compression and tension loads, complex projects can be achieved. Applications are for industrial and energy projects where irregular structures present challenges for standard modular equipment. The anti-corrosion and non-sparking elements of Proscaf element are also a benefit in these applications.

WEIGHT SENSITIVE JOBS

- Proscaf aluminium is perfect for weight sensitive projects.

- Rooftop platforms

- Remote projects requiring lengthy cartage.

- Projects only accessible by helicopter. Scaffold on islands etc.

- Commercial building maintenance.

- Silo & boiler maintenance.

- Marine & superyacht painting work.

Explore premium, job-ready scaffolding systems and accessories at Proscaf Australia’s trusted supplier for high-quality, innovative site safety solutions.

SafeSmart Hinkley Point C Best Practices