The brief from Qantas Engineering department was to design and install a mobile cabin access to the rear exit door of the B737. The platform needed a sturdy deck that would fit with the contour of the plane and remove any fall from height hazard during mandatory works on this area.

The issues Proscaf were faced with was the potential difficulty in easily moving a platform of this size (5mx 5m) and still maintaining a heavy-duty rating for the platform. Our design would need to minimise the number of wheels the platform operated on. Added to this was the 24-hour lead time that was crucial to Qantas to meet the deadline of the next arriving aircraft.

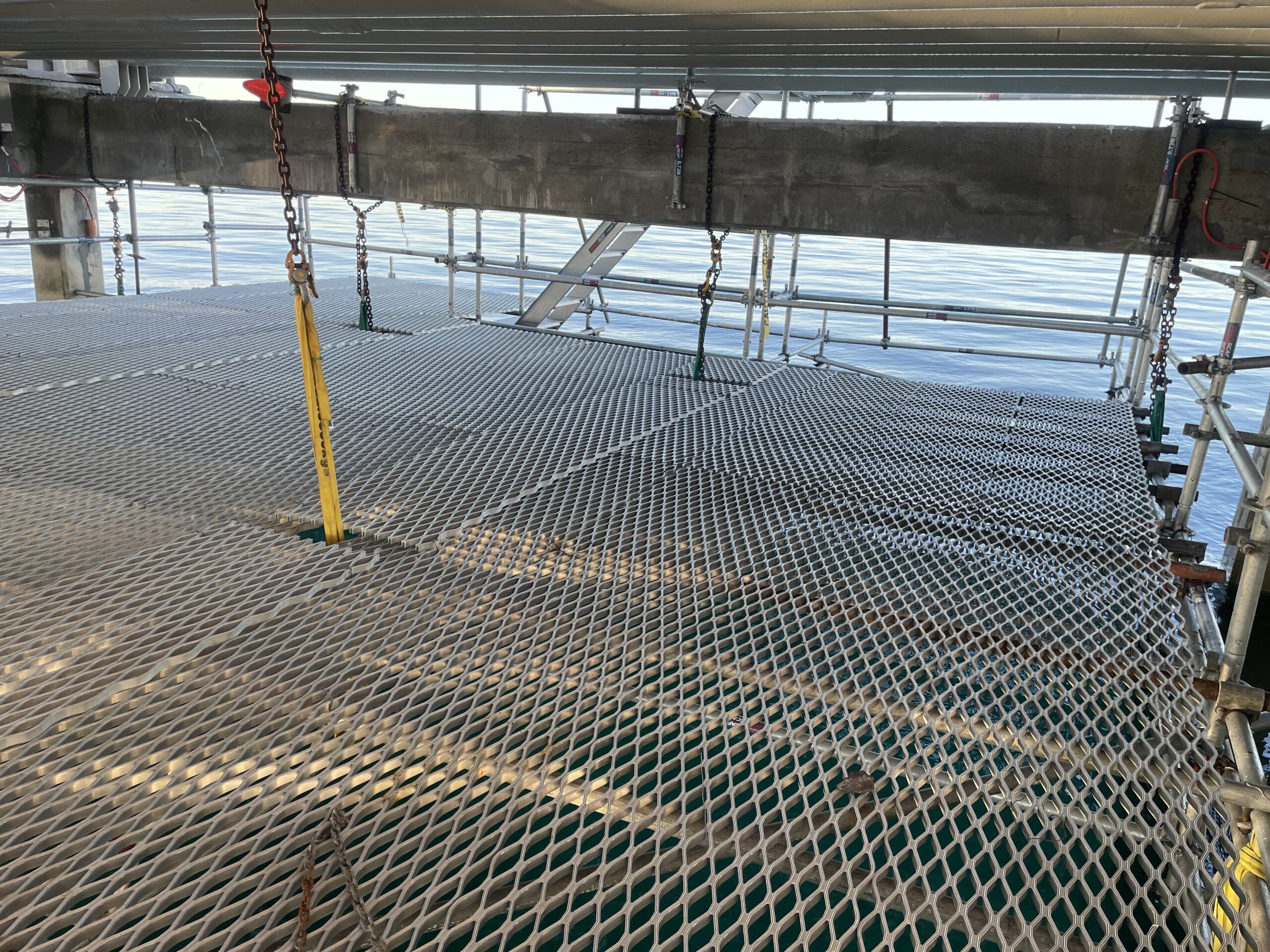

To achieve this, the Proscaf design team settled on the use of our Proscaf modular scaffolding system. Included in this was our heavy-duty 5m U lattice girder beam, which allowed us to eliminate 33% of the required wheels needed with conventional scaffolding. We suspended a stair access off the primary platform and utilised our portable stair products to overcome the lower steps. The weight of the unit was controlled by removing the majority of the steel decks usually required and laying a timber and ply platform on top of the framework. This also allowed us to measure and cut the small, cantilevered section to the contour of the plane.